Showing all 14 results

-

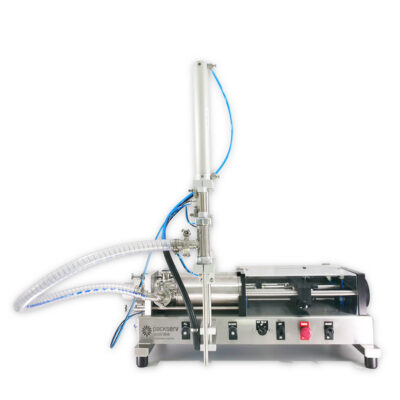

Make: PackservCode: PFM-3-BUF

-

Make: PackservCode: PFM-3-BUF-A

-

Make: PackservCode: PFM-3-BUF-NA

-

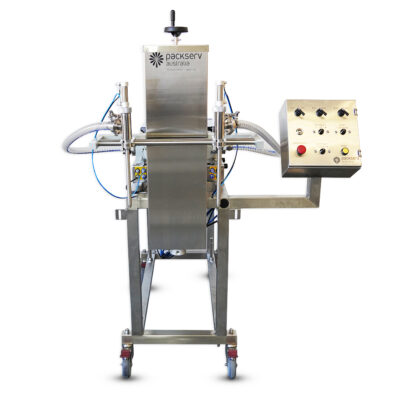

Make: PackservCode: PFM-5-BUF

-

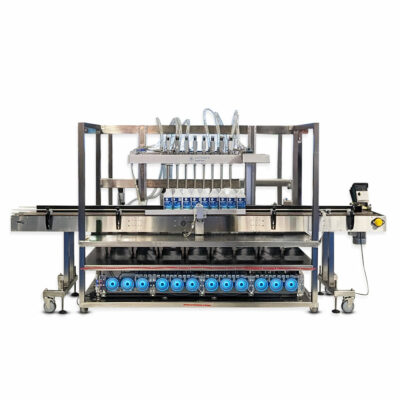

Make: PackservCode: PFM-8C-TL

-

Make: PackservCode: PFM-5-BUF-A

-

Make: PackservCode: PFM-5-BUF-NA

-

Make: PackservCode: PFM-5-2C

Showing all 14 results

Four Head, Twin Head and Single Head Filling Machines for Sale or Rent

Packserv Four Head, Twin Head and Single Head Fillers are a vital component in many manufacturing industries that require precise and consistent product packaging. These machines are designed to fill containers with various liquids, creams, and powders, depending on the industry’s needs. They come in different shapes, sizes, and capabilities to suit various industries’ needs.

Packserv also offer quality capsule/tablet counters, notably our standard Tablet and Capsule Counter and our Automated Tablet and Capsule Counter.

What are liquid filling machines, and how do they work?

Four Head, Twin head and Single Head Fillers, also known as piston fillers, are machines designed to fill containers with precise amounts of liquid, cream, or powder. They work by using a piston that draws the product from a hopper or a reservoir and dispenses it into the container. The piston’s movement is controlled by a pneumatic or electric system that ensures consistent and accurate filling. Single, twin and four head fillers are used in various industries, including food and beverage, pharmaceuticals, cosmetics, and chemicals.

What are the benefits of four head, twin head and single head liquid filling machines?

Filler machines offer numerous benefits, including:

Precise and consistent filling

Single, twin and four head fillers ensure that each container is filled with the same amount of product, which reduces waste and improves product quality.

Time-saving

Filler machines can fill containers much faster than manual filling, which improves production efficiency and reduces labour costs.

Versatile

Four, twin head and single head fillers can handle different types of products, including liquids, creams, and powders.

What are the different types of head fillers?

Filler machines come in various types, including:

Manual single head fillers

These machines require manual operation, which makes them suitable for small-scale production.

Semi-automatic head fillers

These machines have automated filling processes, but require manual loading and unloading of containers.

Automatic head fillers

These machines have fully automated filling processes and can handle high-volume production.

What features should I consider when buying or renting a single head filler or twin head filler or four head filling machine?

When buying or renting a single or twin head or four head filler, consider the following features:

Product viscosity

Consider the product’s viscosity to ensure that the machine can handle it.

Container size and shape

Choose a machine that can accommodate the size and shape of your containers.

Filling volume

Choose a machine that can fill your containers with the required volume.

Speed

Consider the machine’s filling speed and how it fits into your production line.

Maintenance

Consider the machine’s maintenance requirements and the availability of spare parts.

How do I maintain a filling machine?

Maintaining a single head filler, twin head filler or four head filler is essential for its optimal performance and longevity. Here are some tips for maintaining a filler:

- Clean the machine regularly to prevent product build-up and contamination.

- Lubricate the machine’s moving parts to prevent wear and tear.

- Replace worn-out parts promptly to prevent machine breakdowns.

- Perform regular inspections and maintenance checks to ensure the machine’s proper functioning.

Buy or rent your single, twin head or four head filler with Packserv

Fillers are essential machines in many manufacturing industries, providing precise and consistent product filling. Choosing the right type of filler machine and considering important features and maintenance requirements can improve your production efficiency and product quality.

Whether you’re buying or renting a single head filler, twin head filler, four head filler or tablet/capsule counter, consider its suitability for your product, container size and shape, and production volume. Maintaining the machine regularly can also ensure its optimal performance and longevity.

If you’re looking to buy or rent a filling machine, do your research and choose a reputable supplier like Packserv that offers quality machines and reliable customer support in Australia. With the right head filler, you can improve your production efficiency, reduce labour costs, and produce consistent and high-quality products.