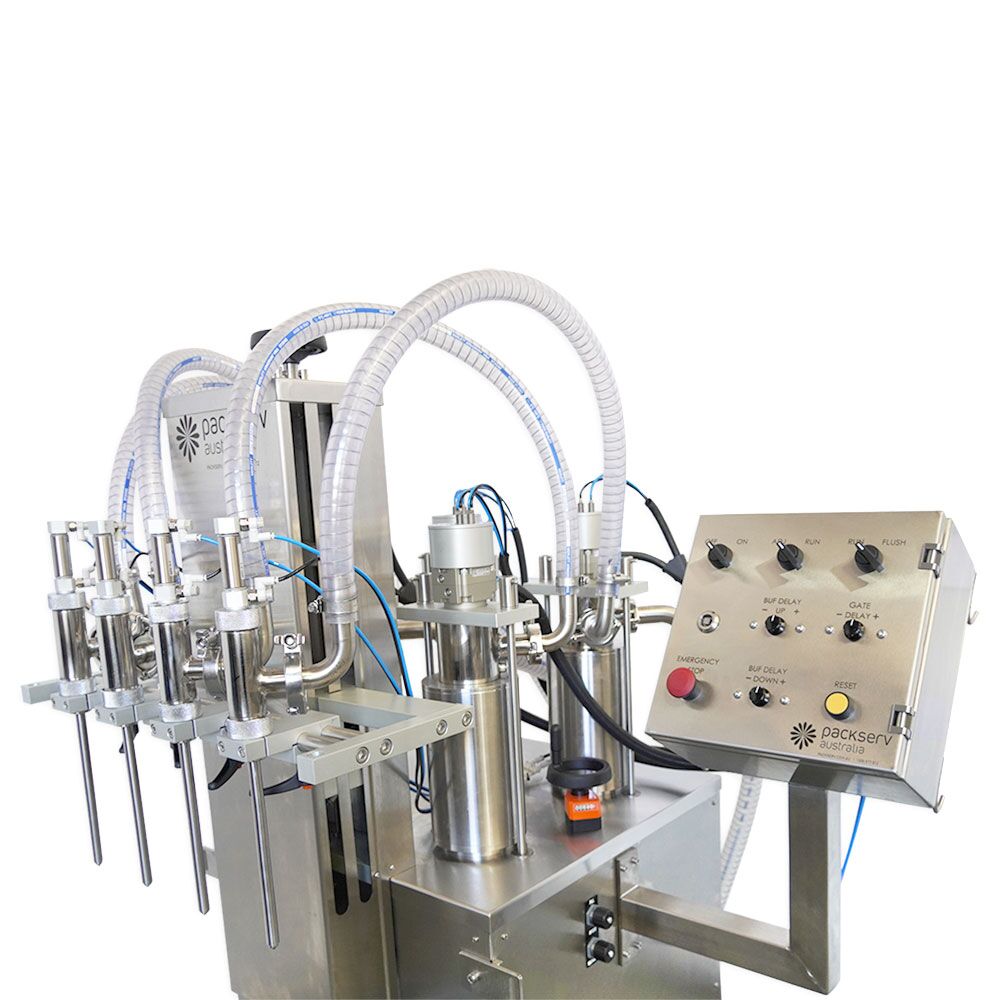

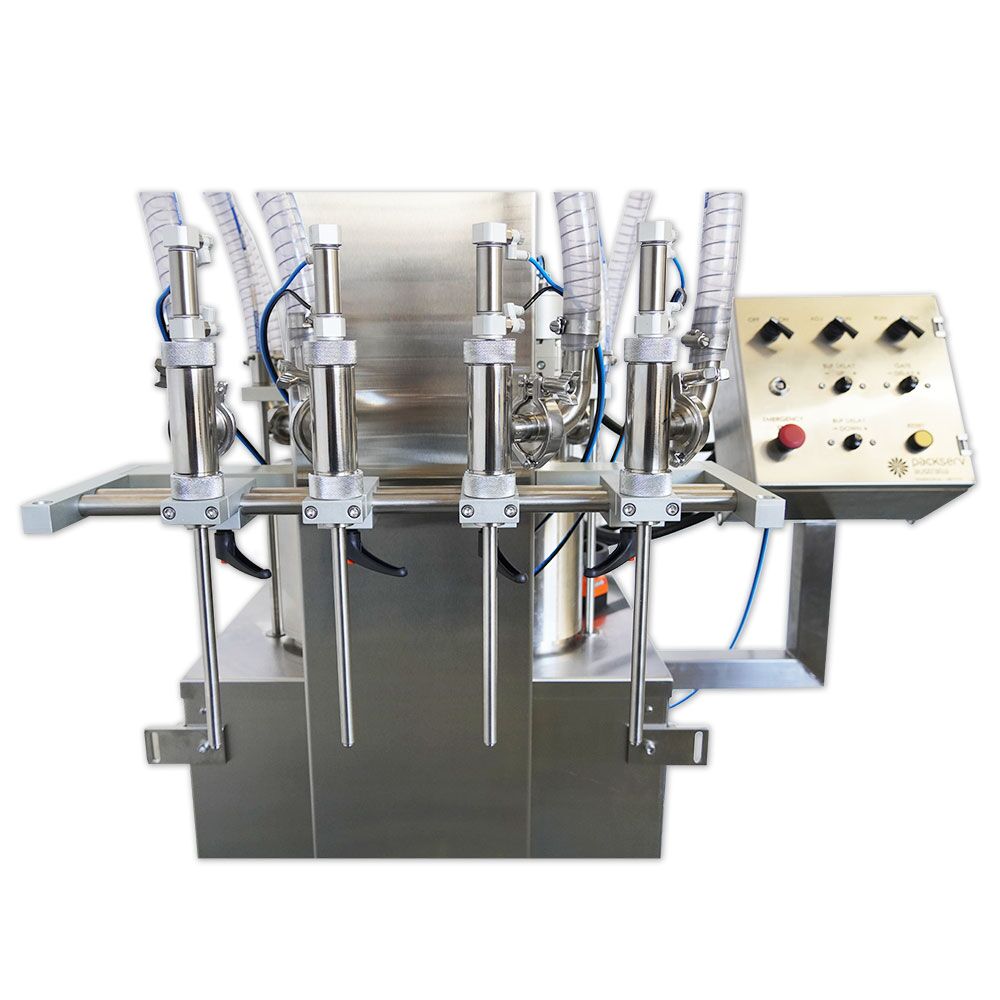

Our PFM-4C Four Head Auto Filler is an automatic liquid and lotion filling machine that is both user friendly and versatile. The heavy duty, all pneumatic design of the PFM-4C is compact, reliable and easy to clean.

This machine is designed for completely automatic function and use in a full-scale production line. The PFM-4C features a welded and polished frame with lockable castors allowing connection to a continuously running slat conveyor. Also comes complete with “no bottle no fill” safety device and container gating system.

The PFM-4C Four Head Auto Filler also comes standard with positive shut-off nozzles and a bottom up fill assembly. The valve system of the PFM-4C handles all types of free flowing liquid products from thin liquids to lotions. A special valve is also available for hot fill applications (i.e. >65°C 149 F). This machine will even package products with suspended solids. A task that previously required two different types of filling machines or expensive change parts.

The cylinder design of the Four Head Auto Filler enables quicker dismantling and easier, more thorough cleaning of wet parts. The supply method of product to this machine is run through a stainless steel manifold system connected preferably by 2″ or 3″ transfer hose connected directly to a storage/mixing vat or IBC.

Finally we have enclosed the stroke adjuster and air/product cylinder drive assemblies within a lockable steel cabinet.

*Rent: Brand and model may vary. The machine will be identical in function.

See Also: Packserv Liquid Filling Machines | Packserv Australia

Reviews

There are no reviews yet.